COMMANDbatch CP

Precision Production Equals Cost Efficiency

commandbatch cp

Precision Production Equals Cost Efficiency

INTELLIGENT CONTROLS FOR MANUFACTURED CONCRETE

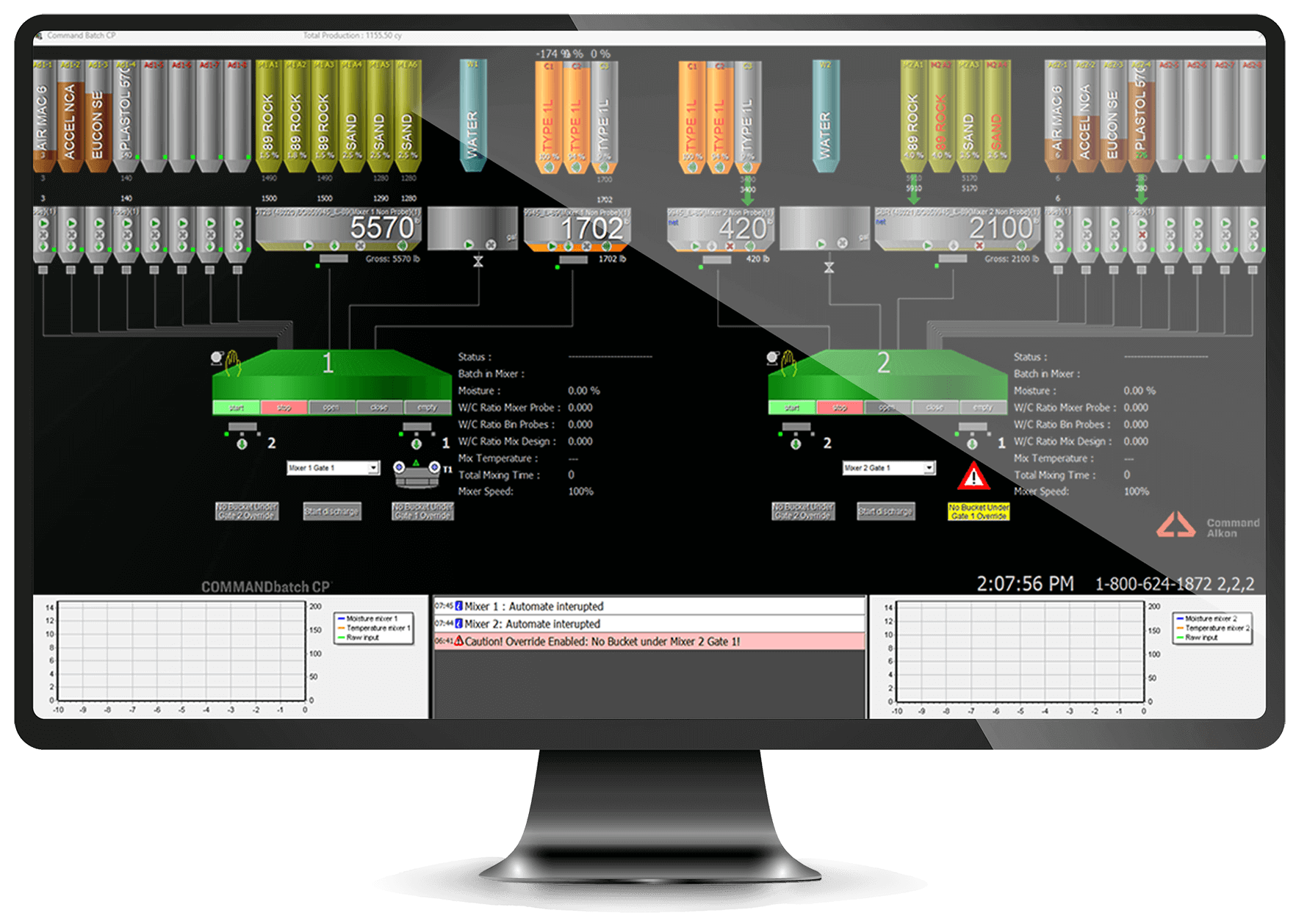

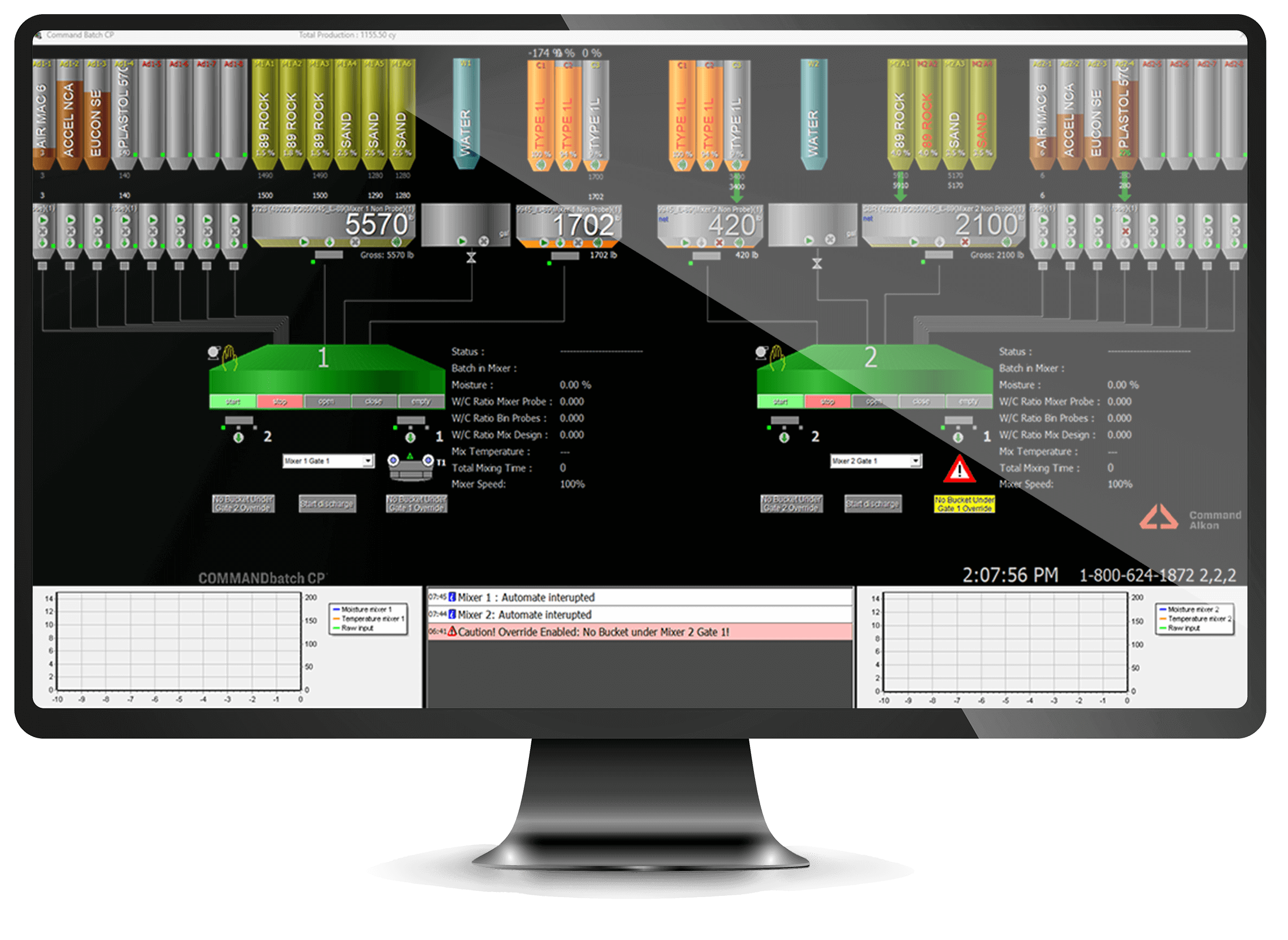

COMMANDbatch CP is a versatile solution tailored to meet your production requirements, whether you are running a small operation or a large plant with complex equipment. Control the complete process from aggregate section to multiple scales and mixers, delivery buckets, color system interfaces, and overhead cranes. Optimize production while significantly reducing costs associated with rework, waste, and revenue losses.

“Our ability to now monitor changes in real time is extremely valuable, allowing us to see our production progress at any time. The efficient and optimal use of our lanes improves the speed of our operations and increases the amount of money our business can make.”

– Bjorn Aaldering, Project Engineer at VBI Huissen

VISUALIZE & MONITOR YOUR ENTIRE PROCESS

Monitoring capabilities reveal key insights into every production step, from weighing to mixer and bucket clean cycles. View both historical and real-time insights around water dosing, mixing, coloring and more. Adjust mix water and prioritize mixes and delivery directly from the plant floor.

MANAGE MOISTURE & WATER FOR CONSISTENT QUALITY

Advanced control algorithms in combination with an array of automatic sensors in aggregate bins and mixers guarantee superior product quality and performance. Gain precise control over water dosing and aggregate moisture, ensuring top-tier quality for SCC, dry cast, or any manufactured concrete product.

Reduce Costs & Improve Quality

45+

Request a Demo